CNC Bits VS Router Bits

In the world of woodworking and computer numerical control (CNC) machining, the tools used play a crucial role in achieving desired outcomes. Two common types of cutting tools used in these processes are CNC bits and router bits. While they may appear similar at first glance, there are distinct differences between the two. In this article, we will delve into the disparities between CNC bits and router bits, shedding light on their design, functionality, applications, and compatibility.

Design and Functionality

CNC Bits: CNC bits, also known as end mills, are specifically designed for use in computer-controlled milling machines or CNC routers. These bits feature a shank that is inserted into a collet or chuck, while the cutting portion extends outward. CNC bits are typically made from solid carbide or high-speed steel (HSS) and come in various shapes, such as flat end mills, ball nose end mills, and V-bit cutters. They are engineered with sharp flutes and cutting edges, enabling them to remove material with precision and efficiency.

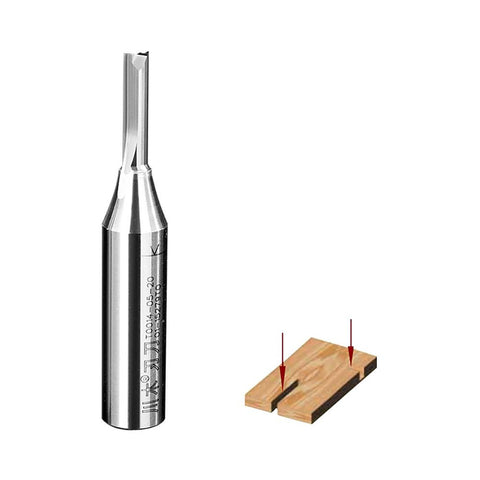

Router Bits: Router bits, on the other hand, are primarily designed for use in handheld or table-mounted routers. These versatile cutting tools are used in woodworking for a wide range of tasks, including edge profiling, joinery, decorative inlays, and more. Router bits are available in diverse profiles and cutting geometries, catering to specific woodworking applications. They are commonly made from high-speed steel, carbide-tipped steel, or solid carbide. Router bits feature a shank that is inserted into the router's collet, while the cutting portion extends beyond the base of the router.

Applications

CNC Bits: CNC bits excel in precision cutting, drilling, and milling operations performed by computer-controlled machines. They are frequently used in industrial settings, where accuracy, repeatability, and high-speed production are paramount. CNC bits are employed in various fields, including manufacturing, prototyping, signage, and cabinetry. They are capable of machining a wide range of materials, such as wood, plastics, metals, and composites.

Router Bits: Router bits find their application in woodworking tasks that require versatility and hand-operated control. They are commonly used for edge profiling, joinery, template routing, and decorative inlays. Router bits are favored by hobbyists, craftsmen, and professionals alike, as they offer creative freedom and flexibility. Woodworkers utilize router bits to shape edges, create intricate designs, cut joinery, and add decorative details to their projects.

Compatibility

CNC Bits: CNC bits are specifically designed for use with CNC machines, which are computer-controlled and rigid in their operation. These machines provide precise positioning, feed rates, and cutting depths, allowing CNC bits to perform with exceptional accuracy. It is essential to select CNC bits that are compatible with the specific machine and its capabilities. Additionally, CNC bits are often designed to work with specialized tool holders and collets that ensure secure and precise tool retention.

Router Bits: Router bits are designed for use with handheld or table-mounted routers, providing versatility and ease of use. These routers offer manual control, allowing woodworkers to guide the tool along the workpiece. It is crucial to select router bits that match the shank diameter of the router's collet to ensure a proper fit. Additionally, router bits may require specific router accessories, such as guide bushings or templates, to achieve desired results in certain applications.

While CNC bits and router bits share similarities in their purpose of cutting and shaping wood and other materials, they are designed for different applications and machinery. CNC bits are tailored for computer-controlled milling machines, delivering precision and efficiency in industrial settings. Router bits, on the other hand, cater to handheld or table-mounted routers, providing versatility and manual control for woodworking projects. Understanding the distinctions between CNC bits and router bits enables woodworkers and machinists to select the appropriate tool for their specific needs, ensuring optimal performance and desired results in their respective applications.